Aries Limited

16 West Jackson Street

Medford, OR 97501

Phone: 650-279-6609

Email: Sales@amuffler.com

Rebuilt Model B Engine

This Model B engine is a diamond block made in the late 1930’s for use as an industrial engine. It has a counterbalanced crankshaft with inserted main bearings. The block is sleeved which makes for better cooling. The pistons are .030” oversize Egge Pistons, the same ones recommended for the Burtz Engine. The connecting rods are new, inserted rods from Antique Engine Rebuilding. The valves are stainless steel, with oversize intake valves for better breathing. The camshaft was reground by Jim Brierley, a touring grind. It provides good low-end torque and good high-end horsepower. The head is a 6.5:1 as is the 30-pound flywheel, both from Burtz. The pressure plate is a Ford V-8, which means less pedal pressure when shifting.

The engine has been test run and is strong, quiet and smooth. The Model B engine is a vast improvement over the Model A engine. The oiling system on the Model A is a gravity fed system, while Model B has pressurized main bearings and cam bearings.

The surface area of the bearings is 20% greater, while the cross section of the output shaft is 50% greater than the Model A.

This means an almost indestructible engine. Its durability is very close to that of the Burtz Engine.

The price does not include the water pump, fan, distributor, manifolds, carburetor or starter. These items can be supplied at additional cost.

We can also supply an FSI automatic, solid-state distributor, which would be timed at our shop.

Price is $6,500 outright, no core required.

About the Engine Builder - Joe Davis:

Joe learned how to build Model A Ford engines from his Dad. When Joe was 16, he bought his first Model A. It needed most everything and getting it running and stopping reliably was of first order. Dad had years of experience not only with Model A’s but also heavy diesel tractors and earth moving equipment. He showed Joe how to scrape bearings and set the clearance on the mains and the rods. Cylinders were honed and new rings installed, wrist pins checked, and ring gaps checked. Valves were lapped in by hand and clearance adjusted by grinding. The engine was a success, Joe put over 20,000 miles on it, driving over and around the Sierra Mountains on countless camping trips. Two years later, he built a counter-balanced B engine with a Cragar overhead valve conversion and two Stromberg 97 carburetors. It was set up with juice brakes and a Columbia overdrive rear axle. It went very fast and after 6,000 miles, he sold it when some offered a bunch of money for it.

Just like then, no stone is left unturned. The babbit is melted out of the blocks, then they are hot tanked and vapor honed to reveal any cracks or flaws. The block is machined in Albany, Oregon to accommodate insert bearings. If the block is over .100 oversize on the bores, we sleeve it. Modern stainless valves and guides are installed; the intake ports are smoothed for beter breathing. We usually use oversize intake valves as well. We use either a Brierly reground cam or a Burtz cam. Both are excellent cams. We rebuild the oil pumps to accommodate an oil filter. We use the Burtz 6 1⁄2 to one head. Connecting rods are from Antique Engine Rebuilders, they are new forgings with inserts. I have built two of the Steve Serr Miller overhead valve setups and that is definitely an option. We use a 30- pound Burtz flywheel and V-8 pressure plate. We can build the engine to accommodate a Model A transmission or a synchromesh Model B transmission.

I have built many other types of antique engines, including several Packard Straight Eights from the early 30’s and 2 Lincoln V-8’s plus a Lincoln Zephyr V-12. I owned and operated Aries Restoration in La Honda for over 10 years where we repaired or restored over 400 cars, including many Model A Fords plus many other Pre-War automobiles.

Options on Setting Up a "B" Engine for Maximum Performance

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

I have built many other types of antique engines, including several Packard Straight Eights from the early 30’s and 2 Lincoln V-8’s plus a Lincoln Zephyr V-12. I owned and operated Aries Restoration in La Honda for over 10 years where we repaired or restored over 400 cars, including many Model A Fords plus many other Pre-War automobiles.

Below is a photo collage of an engine rebuild on a 1922 Lincoln V-8 I did several years ago. Click on the image to enlarge.

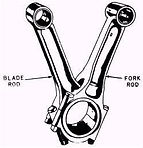

I have built 3 Lincoln Engines, all were the “L” series, built from 1921 to 1930. In 1926 they went from 357 CI to 384 CI. As were most larger engines of the day, the crankcase was separate from the cylinders and made of aluminum alloy. It is a 60 degree V-8 as most today are 45 degrees between the cylinders. Other features included roller lifters, very quiet, a drilled crankshaft with full pressure oiling to cam and crankshaft. The engine a chassis was designed by Henry Leland back in 1921 when he started the Lincoln Motor Company. Henry Leland had made his money during World War I, making over 6,000 of the Liberty Aircraft engines. Used in the Jenny airplane and others. It had many similarities with the Lincoln engine. The Lincoln engine being a much smaller engine. One feature on both engines is the Fork and Blade design of the connecting rods. Instead of having rods side by side on the journal as is typical today, one rod is spit with a rod in the middle. I show a drawings of one. On radial engines you could have 7 or 10 of these intermingled connecting rods working on one shaft, depending on the number of cylinders of the radial engine.

These engines were flat heads, with priming cups for ether, as the gasoline was very low octane. Rebuilding involved some very tricky Babbitt work, done by Tom Holthaus of Quality machine. The cars were heavy, but the engines had good torque and a top speed of 90 miles per hour. I can attest to that as I have done it. A timing chain and roller lifters made the engine extremely quiet and smooth. Standing next to a car that was running one might not notice it was running. The Lincoln factory had a 2 ½ mile track and they ran each chassis for 200 miles around the track before it was sent to have the body installed. In 1932 Lincoln came out with a V-12 by adding four more cylinders to this engine. These engines were even smoother, accelerating smoothly and powerfully. This engine was used up until the late 30’s, when they were discontinued.